Our Services

Types of Spray-painting Booths and Airflow ventilation systems

There are three types of Spray-painting Booths recognised in Standard AS/NZS 4114. They are:

1. Open-fronted

2. Enclosed-type batch booth

3. Tunnel or Production booth.

Booths can also be a combination of types

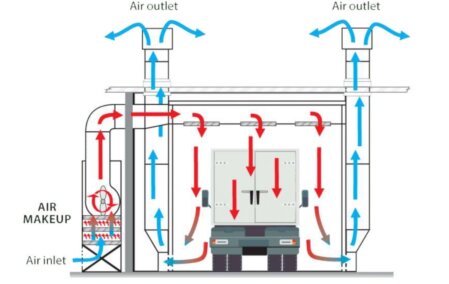

Air-flow types include:

1. Full down draught

2. Semi-down draught

3. Cross-flow system

4. On floor down draught

5. Design certified Hybrids

Do you need assistance?

Having decided on whether to build one or buy an imported unit, the next question is about building and installing it. Your ELECTRICIAN can help with that and we can help both of you.

Whether it's to understand the level of certification required for the repair or replacement of parts or, if you want to modify your booth, involve your ELECTRICIAN or give us a call, I'm sure we can help.

If you're ready to have your annual Location Compliance Certificate (LCC) reissued, have you checked that your documentation and electrical certificates are up-to-date. This includes your maintenance log. When you're ready... contact your nearest Site Certifier .

If your electrical equipment needs to be inspected, give us a call.

Everyone has a job to do but who does what?

Your ELECTRICIAN will complete the electrical installation work and then issue an Electrical Certificate of Compliance plus an Electrical Safety certificate. They will also carry out any maintenance work required.

An ELECTRICAL INSPECTOR's job is to verify that the equipment operates correctly then inspects and certifies both the equipment and power supply, They will issue a Record of Inspection and will then submit a record to the WorkSafe NZ / Energy Safety's high-risk register. An electrical Periodic Assessment is then required every three years.

Your LOCATION COMPLIANCE CERTIFIER will carry out and annual inspection/audit and issue a Location Compliance Certificate. They will need to see a copy of an electrical Periodic Assessment issued by an inspector before validating the LCC.

And YOU. You are responsible for maintaining and operating your equipment in the safest way possible. You will also need to record all maintenance activities. We can help with that.

Applicable Standards

The Primary reference for all electrical installations in New Zealand is The Electricity (Safety) Regulations. The 'Regs' direct installers to AS/NZS 3000 (Wiring Rules) for general requirements and then to specific Standards. AS/NZS 4114 is the 'go-to' Standard for Spray Painting Booths, Designated Spray Painting Areas and Paint Mixing Rooms. It contains the requirements for Design, Construction and Testing. It also sets out the requirements for installation and maintenance, Inspection and certification. Other requirements may also apply which are covered in AS/NZS 60079 Parts 14 and 17. If the booth is fitted with a gas burner, there are additional requirements set out in the Gas Safety and Measurement Regulations.

MANUFACTURERS OF PRODUCTS WE ARE FAMILIAR WITH

Click on their logos for more information